High-protein concentrated soy protein (SPC) has become an indispensable ingredient in the food and feed industries due to its rich nutritional value and excellent functional properties. This article delves deep into the modern extraction process of SPC, offering valuable insights for food and feed manufacturers aiming to enhance product quality and competitiveness.

In the food and feed sectors, the demand for high-quality protein sources is on the rise. SPC, with its protein content of ≥70%, has emerged as a popular choice. In the food industry, it is widely used in meat products, bakery items, and dairy substitutes. In the feed industry, it is an essential component in livestock and poultry feeds. The high protein content not only improves the nutritional value of products but also enhances their functional properties, such as water retention and emulsification.

The production of SPC involves a series of well - defined steps:

Let's take a closer look at the key technical points in each step:

Ethanol extraction is an effective method for removing sugars from soybeans. By controlling the ethanol concentration, temperature, and extraction time, a high - quality SPC product can be obtained. Typically, an ethanol concentration of 70% - 80% and an extraction temperature of 40 - 50°C are used, which can remove up to 90% of the sugars.

Low - temperature drying at around 50 - 60°C helps to preserve the biological activity of the protein. This ensures that the SPC retains its functional properties, such as gelation and foaming ability.

Ultra - fine grinding reduces the particle size of SPC to less than 100 microns, significantly improving its solubility. This makes SPC more easily absorbed by the human body or animals, enhancing its nutritional value.

Compared with traditional processes, modern SPC production equipment offers several significant advantages:

| Aspect | Traditional Process | Modern Equipment |

|---|---|---|

| Automation | Low, requiring a large amount of manual labor | High, reducing human error and improving production efficiency |

| Energy Efficiency | Low, consuming more energy | High, with advanced energy - saving technologies |

| Product Stability | Poor, with inconsistent product quality | Good, ensuring stable protein content and quality |

Here are some typical application scenarios of SPC:

In meat products, SPC can be used as a binder and water - retaining agent. Adding 3% - 5% SPC to meat products can increase the water - holding capacity by 10% - 15%, improve the texture, and reduce production costs.

In piglet feed, SPC provides high - quality protein, which is easily digested and absorbed by piglets. A diet containing 5% - 8% SPC can significantly improve the growth performance of piglets, increasing their daily weight gain by 10% - 15%.

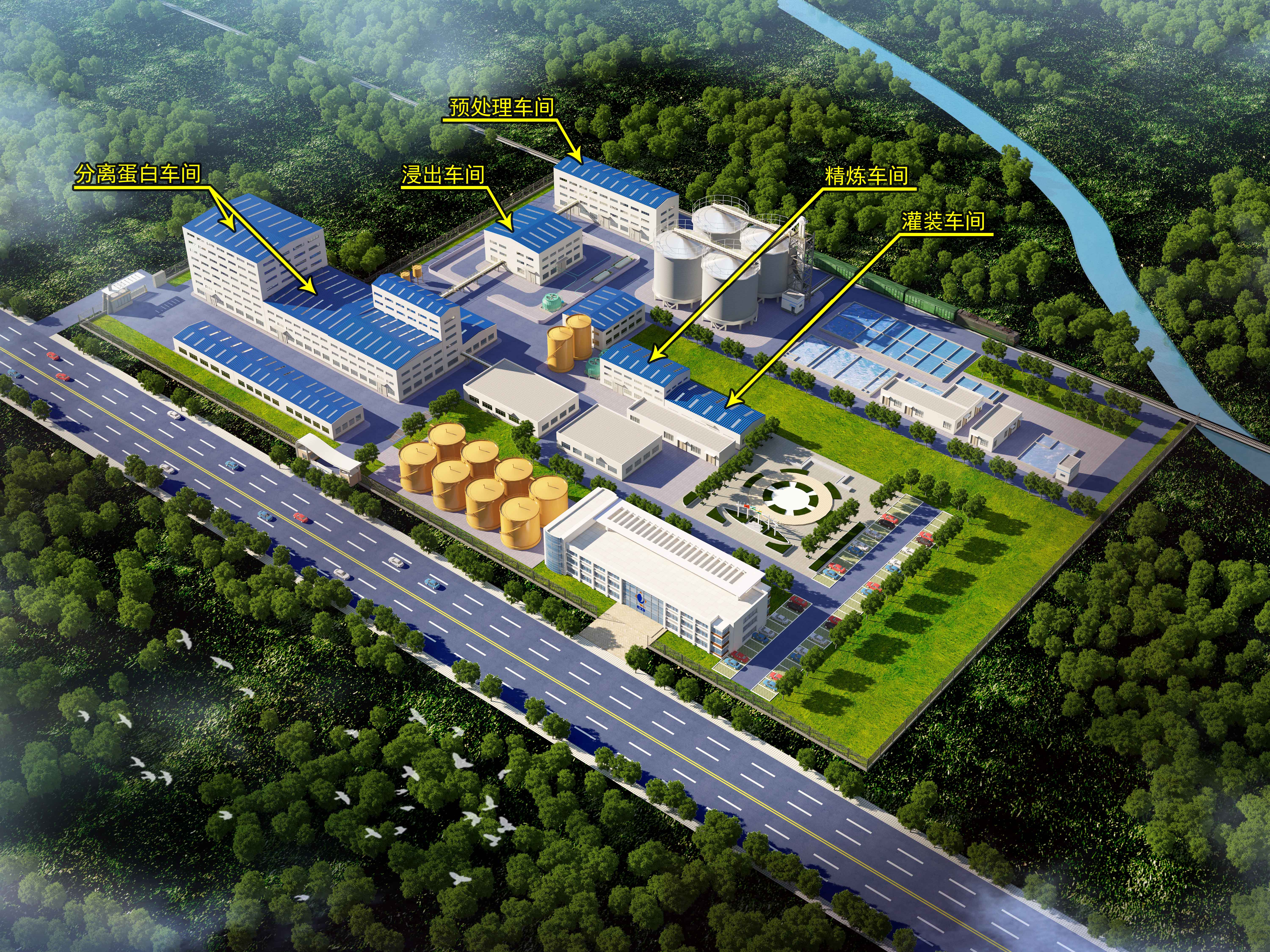

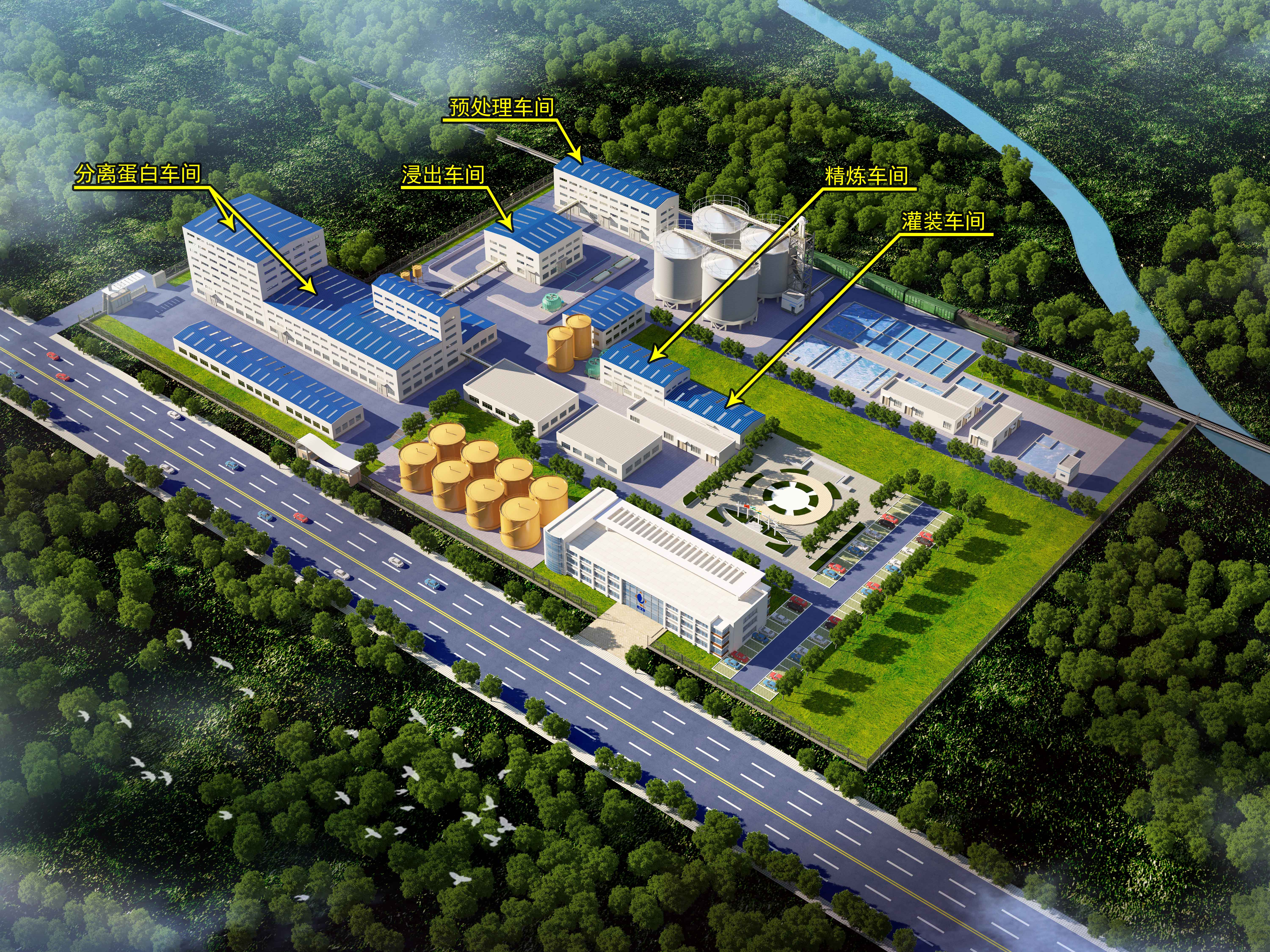

Penguin Group offers state - of - the - art SPC production equipment and comprehensive service solutions. Our equipment is designed with advanced technology, ensuring high - efficiency production, energy conservation, and product quality stability. We also provide customized technical support and after - sales service to meet the specific needs of different customers.

If you are looking to optimize your SPC production process and enhance product competitiveness, Penguin Group is your reliable partner. For a customized SPC production equipment solution, please contact us to get an exclusive technical evaluation report.