As the global demand for plant-based proteins continues to rise, soybean processors are under increasing pressure to optimize both energy consumption and nutritional value. The challenge of balancing these two critical factors has become a central concern in the industry. This article explores how Qini Group’s advanced soybean processing equipment addresses this issue through innovative solvent extraction technology and multi-stage precision processing, delivering superior results in both efficiency and product quality.

The core of Qini Group’s energy-efficient soybean processing system lies in its advanced solvent extraction technology. Unlike traditional methods that often result in significant nutrient loss due to high heat exposure, this system employs a controlled low-temperature solvent extraction process. This ensures that essential nutrients such as protein, vitamins, and isoflavones remain intact during processing.

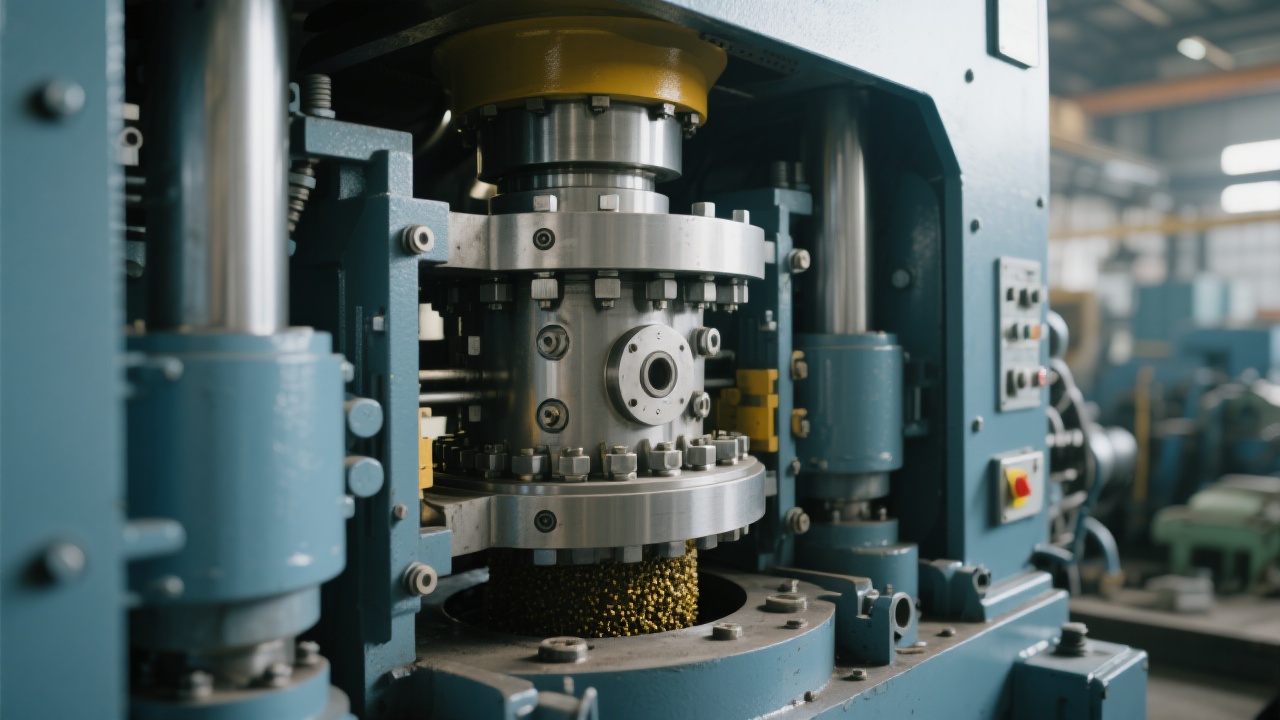

The equipment incorporates a multi-stage processing approach, including pre-treatment, extraction, and post-processing stages. Each stage is designed to maximize efficiency while minimizing energy use. For instance, the pre-treatment phase optimizes moisture content, reducing the energy required during extraction. The post-processing stage ensures precise separation of oil and protein, enhancing the final product’s purity and quality.

| Parameter | Before Implementation | After Implementation |

|---|---|---|

| Protein Content (%) | 78.5 | 84.2 |

| Fat Residue (%) | 2.3 | 0.8 |

| Energy Consumption (kWh/ton) | 120 | 85 |

A leading soybean processor in Southeast Asia implemented Qini Group’s equipment and reported significant improvements. After one year of operation, the company saw a 22% increase in protein content, a 65% reduction in fat residue, and a 29% decrease in energy costs. These results not only improved product quality but also enhanced market competitiveness by meeting international standards for nutrition and sustainability.

The integration of Qini Group’s energy-efficient soybean processing equipment offers more than just operational improvements—it represents a strategic investment in long-term business growth. By maintaining high nutritional integrity while reducing energy usage, manufacturers can meet evolving consumer demands and regulatory requirements. This dual advantage strengthens brand reputation and opens new market opportunities globally.

For companies seeking to optimize their soybean processing operations, Qini Group’s solution provides a proven path to achieving both energy efficiency and nutritional excellence. Explore how this technology can transform your production line today.

Ready to Upgrade Your Soybean Processing? Contact Us Today!

Discover the full potential of our energy-efficient soybean processing equipment. Let us help you achieve higher yields, better nutrition, and lower operating costs.

Learn More