The production of high-protein soy protein concentrate (SPC) demands a precise and optimized extraction process, ensuring protein purity exceeding 70% while effectively removing anti-nutritional factors. This article delves into the core techniques from low-temperature defatted soybean powder extraction using food-grade ethanol to subsequent extrusion, solvent removal, drying, and superfine grinding. Manufacturing engineers and process specialists will gain actionable insights to refine their production lines, achieving superior functional performance for food and feed applications.

The SPC manufacturing workflow is a multi-stage process where each step critically influences the final product’s quality. Starting with selecting defatted soybean flour with protein content typically around 50-54% under low temperature, the raw material's integrity is pivotal for downstream processing. The flour undergoes ethanolic extraction (usually 65–75% food-grade ethanol) at carefully controlled temperatures (<45°C) to solubilize the soluble carbohydrates and anti-nutrients while retaining the insoluble proteins.

Subsequent extrusion compacts the protein matrix and enhances denaturation, facilitating easier removal of residual solvents and anti-nutritional factors like trypsin inhibitors and phytic acid. The solvent desorption stage employs vacuum drying at temperatures below 90°C to prevent protein denaturation, securing high bioactivity retention. Finally, superfine grinding refines particle size distribution to improve solubility and textural properties critical for application versatility.

Choosing high-quality defatted soybean flour with low residual oil content (<1.5%) and controlled moisture (<12%) ensures minimal lipid oxidation, which otherwise compromises protein purity and shelf life. Studies report that starting with raw material protein content variation of ±2% can shift final SPC purity by up to 5%, underscoring the importance of stringent supplier quality verification.

Anti-nutritional compounds such as trypsin inhibitors, lectins, and phytic acid limit soy protein’s nutritional and functional application. Food-grade ethanol extraction, optimized between 65–75%, reduces trypsin inhibitors by over 85% as reported in recent peer-reviewed trials. Controlling solvent temperature below 45°C prevents protein denaturation while maximizing inhibitor solubilization.

Extrusion with enhanced shear forces aids mechanical disruption of carbohydrate-protein complexes, allowing efficient separation during solvent removal. The residual phytic acid levels post-processing can be curtailed to below 0.5% with optimized solvent desorption parameters (vacuum drying at 85°C for ~30 minutes).

| Process Step | Key Parameters | Impact on SPC Quality | Optimization Focus |

|---|---|---|---|

| Defatted Soybean Flour | Protein 50-54%, Moisture <12% | Baseline protein purity, lipid content | Supplier quality control, low oxidation |

| Ethanol Extraction | 65-75% Ethanol, <45°C, 60-80 min | >85% Anti-nutrient removal | Solvent concentration, temperature regulation |

| Extrusion | 140-160°C, Shear rate control | Protein matrix restructuring | Screw configuration, temperature control |

| Solvent Removal & Drying | Vacuum drying, <90°C, ~30 min | Residual solvent <200 ppm | Vacuum level consistency, temperature precision |

| Superfine Grinding | Particle size 50-80 μm | Improved solubility & dispersibility | Mill type, feed rate, cooling |

SPC must cater to diverse performance specifications according to end-use. For food-grade SPC, higher solubility (above 85%) and a mild flavor profile are critical, which require precise control over drying temperatures and fine particle distribution. In animal feed, cost-effectiveness and robustness against moisture demand slightly coarser particle size (~80 μm) and stable residual oil content below 1.5%.

Case studies demonstrate that tweaking extrusion speed and ethanol percentage by ±5% results in functionality improvements noticed by protein solubility tests (measured by nitrogen solubility index, NSI). Such process flexibility allows manufacturers to tailor SPC to specific client needs without extensive capital investment.

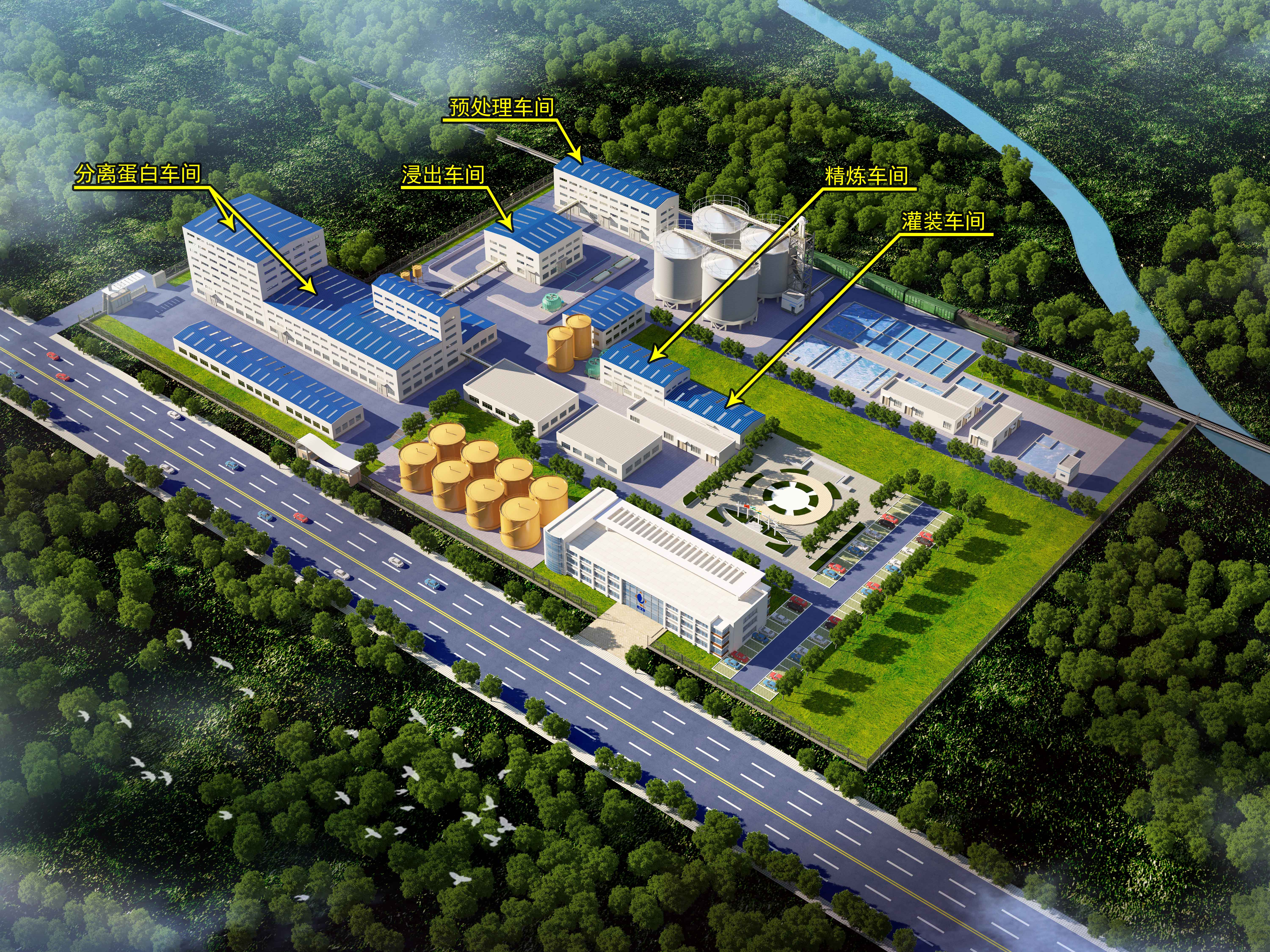

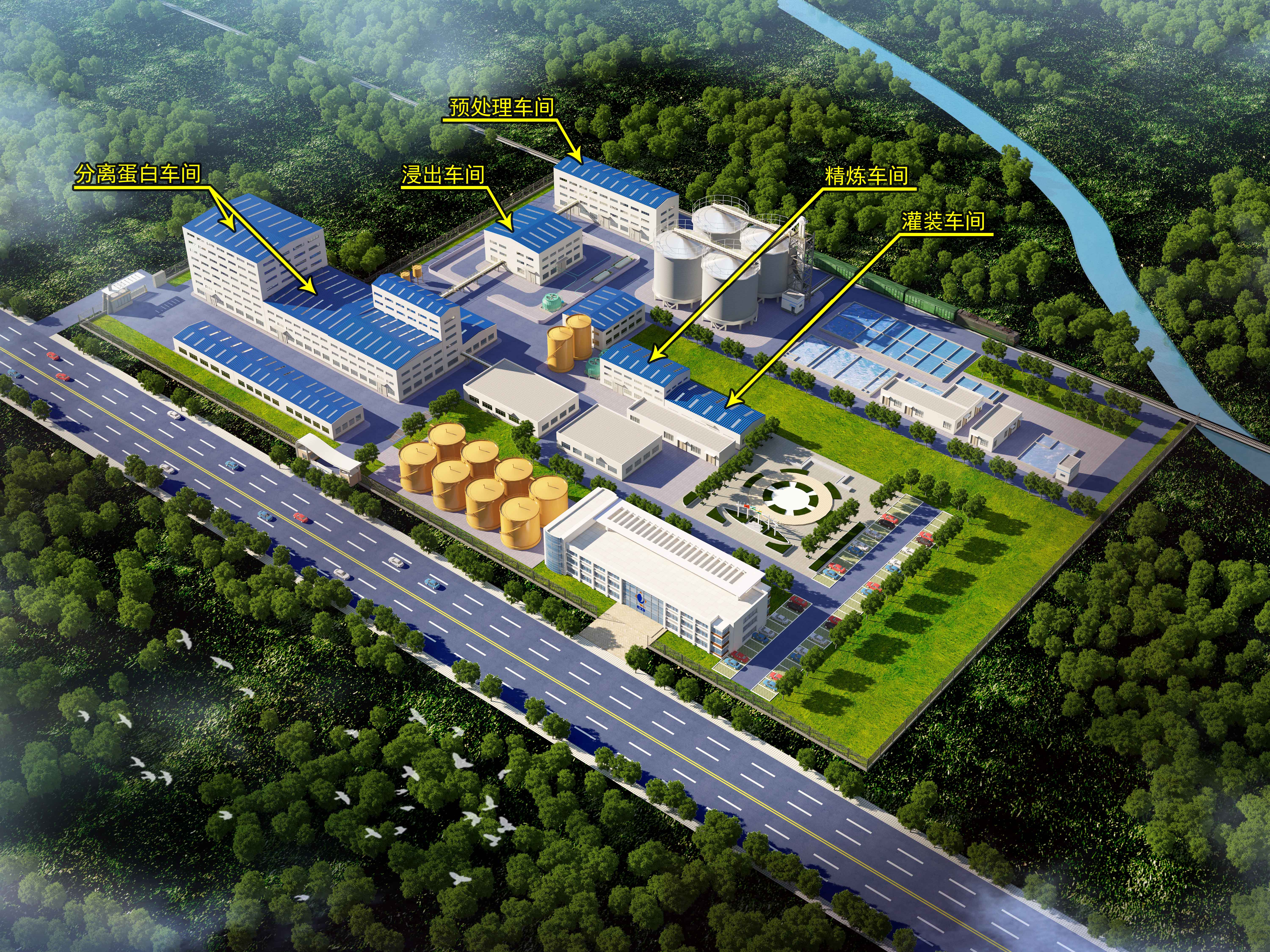

Penguin Group’s advanced equipment lineup integrates cutting-edge control systems to precisely manage solvent extraction, extrusion parameters, and drying profiles, guaranteeing batch-to-batch consistency at scale. Their custom design services also allow adaptation for different plant capacities—from pilot lines of 500 kg/day to commercial scale exceeding 10,000 kg/day—to optimize OPEX and minimize solvent consumption by up to 12%.

Client testimonials confirm improved yield by 8-12% and protein purity enhancements up to 72%, directly attributable to equipment sophistication combined with process advisory support from Penguin engineering teams.

Looking to optimize your SPC production line with tailored solutions? Contact us within 24 hours to receive your customized quote and elevate your protein concentrate output.