As the global demand for high-quality soybean products continues to rise, the challenge of maintaining nutritional integrity while reducing energy consumption has become a critical focus for the industry. This article explores how advanced soybean processing equipment, such as that developed by Penguin Group, is transforming the sector through energy-efficient solutions that preserve essential nutrients and enhance product quality.

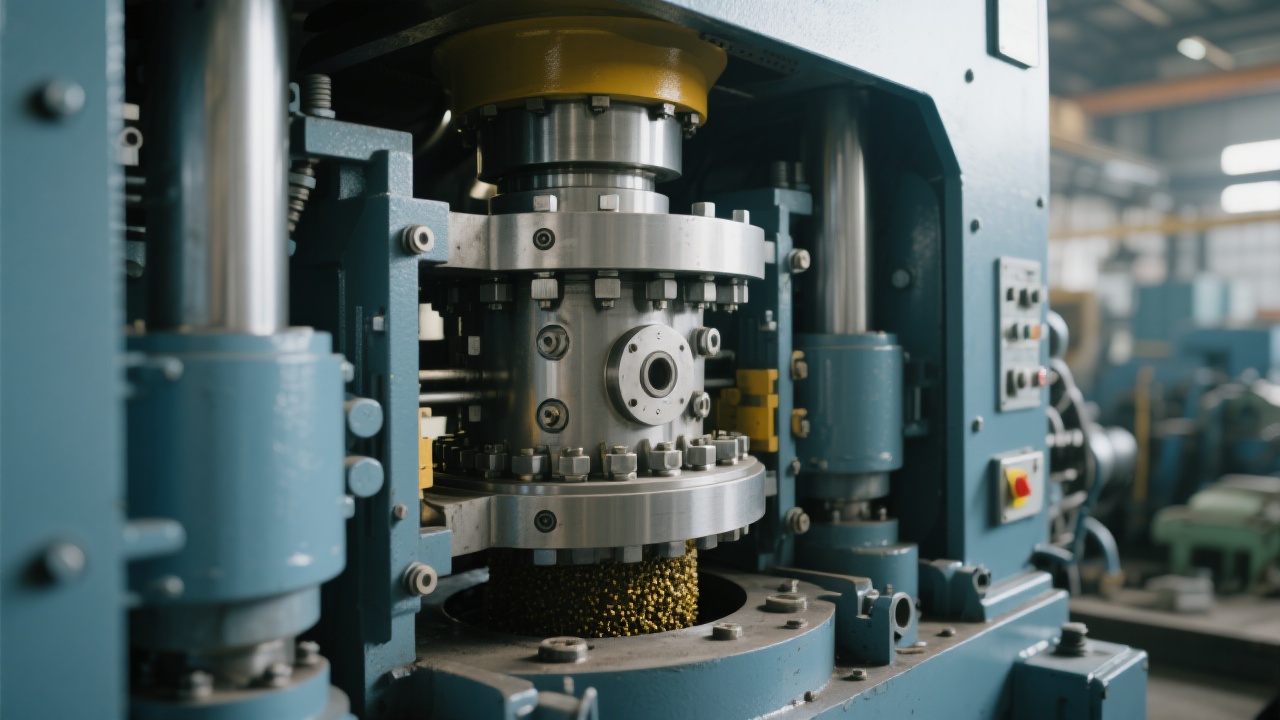

The core of Penguin Group’s soybean processing system lies in its innovative solvent extraction technology. This process integrates several key stages including cleaning, fractionation, dehulling, and deep cold treatment, ensuring that the final product maintains high protein content while minimizing fat levels.

According to internal data from a recent project in Southeast Asia, this system reduced energy consumption by up to 25% compared to traditional methods, without compromising on the quality of the final soybean meal. The use of low-temperature, high-vacuum extraction further enhances the preservation of heat-sensitive nutrients like isoflavones and vitamins.

| Processing Stage | Function |

|---|---|

| Cleaning | Removes impurities and foreign materials from raw soybeans. |

| Fractionation | Separates soybean components for targeted processing. |

| Dehulling | Removes the outer shell to improve nutrient accessibility. |

| Deep Cold Treatment | Preserves sensitive compounds under controlled temperature conditions. |

A leading soybean processor in Brazil recently adopted Penguin Group’s equipment and reported significant improvements in both efficiency and product quality. Before the upgrade, the company faced challenges with inconsistent protein content and high energy costs. After implementing the new system, they observed a 15% increase in protein concentration and a 30% reduction in energy usage per ton of processed soybeans.

“The new system not only improved our product quality but also helped us meet international standards,” said the plant manager. “This has allowed us to expand our export markets and gain a stronger position in the global supply chain.”

Penguin Group’s soybean processing equipment is designed with precision engineering and energy efficiency at its core. With a proven track record across multiple regions, their systems are tailored to meet the specific needs of each client, ensuring optimal performance and long-term value.

Whether you’re looking to reduce operational costs, improve product consistency, or meet stringent international quality standards, Penguin Group offers a reliable and scalable solution that supports sustainable growth.

Ready to transform your soybean processing operations? Contact us today to learn more about our cutting-edge equipment and how it can benefit your business.